Detailed Services

Electrical Projects

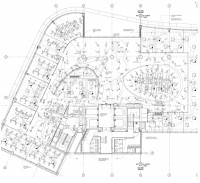

Intalek Limited have a team of experienced draughtsmen and state of the art computers running

AutoCAD & AutoCAD MEP 2011.

We can provide:-

• 2D Paper to CAD Conversion

• Electrical and Mechanical Services Drawings/Schematics

• Architectural/Structural Drawings

• 2D & 3D Plantroom Layouts/Schematics

• 3D Co-ordinated Mechanical, Electrical and Plumbing (MEP) Services drawings.

• Surveys and Record Drawings

If you are an:-

• M&E Contractor looking for Installation or As-Installed drawings

• M&E Consultant requiring M&E Tender or Construction Issue drawings

• Architect or Structural Engineer looking for Tender or Construction Issue drawings

Our engineering draughtsmen have the experience to meet your requirements.

In addition to the above we can provide:-

• Mechanical and Electrical Design Services

• Lighting Calculations and 3D Modelling – ReluxPro

• AO Copy and Colour Plotting Facilities

• Mechanical & Electrical Services Drawings

Contact :- Andy Green

Tel : 01442 230655

Email : cadservices@intalek.co.uk

Address : Unit 8

Sovereign Park

Cleveland Way

Hemel Hempstead

Herts

Hp2 7DA

Portable ApplianceTesting

Introduction

Pat testing or portable appliance testing is an important part of any health & safety policy.

This site is intended as a guide to both the legal implications and to the technical requirements.

The Health & Safety Executive states that 25% of all reportable electrical accidents involve portable appliances. The Electricity at Work Regulations place a legal responsibility on employers, employees and self-employed persons to comply with the provisions of the regulations and take reasonably practicable steps to ensure that no danger results from the use of such equipment. This in effect requires the implementation of a systematic and regular program of maintenance, inspection and testing. The Health & Safety at Work Act (1974) places such an obligation in the following circumstances:

* 1. Where appliances are used by employees.

* 2. Where the public may use appliances in establishments such as hospitals, schools, hotels, shops etc.

* 3. Where appliances are supplied or hired.

* 4. Where appliances are repaired or serviced.

The level of inspection and testing required is dependant upon the risk of the appliance becoming faulty, which is in turn dependant upon the type of appliance, the nature of its use and the environment in which it is used.

The Institution of Electrical Engineers publish the "Code of Practice for In-service Inspection and Testing of Electrical Equipment" (ISBN: 978-0-86341-833-4) . This guide forms the basis for portable appliance testing in the U.K.

Periodic Inspection Reports

What is a periodic inspection? An inspection and series of tests to make sure your electrical installation continue to conform to the national safety standard. A periodic inspection will

* Reveal if any of your electrical circuits or equipment are overloaded.

* Find any potential electric shock risks or fire hazards.

* Identify any defective electrical work.

* Highlight any lack of earthing or bonding.

Tests are also carried out on wiring and fixed electrical equipment to check that it is safe. A schedule of circuits will also be provided, which is invaluable for a property.

Why is a periodic inspection needed? Electrics deteriorate with use and age - and electricity can be deadly. So it’s vital that people aren’t put at risk.

How often is a periodic inspection required? Your electrics should be tested every:

* 10 years for a home.

* 5 years for a business.

* 3 years for caravans.

* 1 year for swimming pools.

Other instances when a periodic inspection should be carried out are

* When a property is being prepared to be let.

* Before selling a property or when buying a previously occupied property.

Who should do it and what happens? A suitably qualified electrician, who will check the electrics against the national safety standard, should carry out all periodic inspections. The inspection should meet BS 7671 – Requirements for Electrical Installations (IEE Wiring Regulations). That’s the technical name for the 850 regulations that are checked in this test.

The inspection takes into account all the relevant circumstances and includes the following

* The adequacy of earthing and bonding.

* The suitability of the switch and control gear. For example an old fusebox with a wooden back, cast-iron switches, or a mixture of both will need replacing.

* The serviceability of switches, sockets and light fittings. All of these may need replacing: older round-pin sockets, round light switches, cables with fabric coating hanging from ceiling roses to light fittings, black switches and sockets mounted in skirting boards.

* The type of wiring system and its condition. For example cables coated in black rubber were phased out in the 1960s, likewise cables coated in lead or fabric are even older and may well need replacing (modern cables use safer pvc insulation).

* That residual current devices are used for sockets that may be used with outdoor electrical equipment.

* The presence of adequate identification and notices.

* The extent of any wear and tear, damage or other deterioration.

* The changes in use of the premises which have led to, or may lead to, problematic wiring.

Periodic Test Quotation

Contact us for a free quotation to arrange a periodic test on your electrical installation with

our skilled engineers to ensure compliance with the current regulations.

Emergency Lighting Inspection, Testing & Certification

How can we help? - Whether you already have a testing and maintenance programme in place or are starting from scratch, we are able to help you fulfil your safety obligations by providing a reliable and cost effective inspection and testing service.

What do we do? - For the majority of clients, we provide annual inspection, testing and certification of emergency lighting. We use fully qualified electricians, experienced in the testing of emergency lighting. We can also supply standard or bespoke log books, so that following the full annual test, a designated member of your staff can quickly and easily perform monthly checks using an easy to follow (tick box style) log book.

Our inspection and testing procedures include the following:

* Luminaire duration testing

* Cleaning of diffusers

* Battery charging functional check

* Labelling of luminaires

* Supply of test results and/or log books

* Supply and fitting of emergency exit directional signs

* Advice on any improvements required

* Certification

General Information on Emergency Lighting

The purpose of emergency lighting testing is to ensure that emergency lights remain fully functional (for the specified duration) during mains electrical failure and that all lighting and exit signs are up to date with current legislation and are adequate for the purpose intended.

BS5266 recommends that emergency lighting systems be regularly serviced by 'competant' persons, these being persons with the necessary knowledge, skills and training to undertake emergency lighting servicing procedures.

Implementation of a periodic system of inspection and testing ensures that emergency lighting systems remain reliable at all times and that in the event of an emergency or power failure, the emergency lighting operates, ensuring that people can safely evacuate the building.

If you have 5 or more employees, you are required by law (under The Regulatory Reform (Fire Safety) Order) to carry out a fire safety risk assessment. We offer a tailored risk assessment service to to help employers fulfil their statutory obligations under the Order.

Routine Testing should be carried out:

Daily - visual check to ensure that emergency lighting systems are operating correctly and that indicators are working. This will be carried out by the 'responsible person' delegated to the task by the organisation/business. Any faults should be logged and corrected asap.

Monthly - Check all luminaires for signs of damage or disrepair. Briefly test all emergency lights to ensure that they operate in the event of mains electricity supply failure. This will usually be carried out by the 'responsible person'. Any faults should be logged and corrected asap.

Annually - A full system inspection and duration test of the emergency lights should be performed by a 'competent person' , this being a person with the necessary skills, training and knowledge to perform emergency lighting maintenance and servicing. Compliance with BS5266 should be considered and produced in the emergency lighting certification report. Any faults should be rectified. Essential Electrical engineers are qualified and experienced in the routine inspection and testing of emergency lighting systems.

Where are Emergency Lights Required?

* Emergency lights are required where artificial lighting is installed

* On escape routes

* Open areas greater than 60 square metres

* Areas of special risk

* Near to stairs and adequate to shine direct light on all treads

* At any change of direction

* At any changes in floor level

* Near to corridors and intersections

* Near to fire fighting equipment

* Near to first aid points

* Outside each final exit point

Periodic Test Quotation

Contact us for a free quotation to arrange a Emergency Lighting Test by our skilled engineers

to ensure compliance with the current regulations.

Fire Alarms

From fire-proof cabling, to smoke-detection devices, manual call points and fire alarm sounders, we will install and programme the entire system with expert care and attention.

We can offer turn key fire alarm systems. We offer design, installation supply and regular maintenance of a wide range of fire alarm systems in the United Kingdom & Ireland. We are not tied to particular suppliers and have a constantly changing stock enusring we get the best deals on parts.

Because of our position we can also eliminate any delays due to product supply - greatly increasing our chances of meeting tight deadlines. Some useful things to know about our fire alarm installations:

* Fire alarm installation of fire alarm systems to hospitals, schools, dockyards and prisons.

* Contracts carried out to a value of £1 million.

* Services include fire alarm system design and installation, emergency schemes.

* Installation of fire alarm systems ranging from single zone controls to multi addressable systems.

Fire Alarm Maintenance Contracts

We have a maintenance plan to suit you at a realistic cost and we won't tie you in to a long term contract. We ask you to sign a non binding 12 month contract instructing us to service your fire alarm equipment.

We then issue a work sheet and test certificate if your system is compliant and you are able to call us at any time if the system develops a fault or you need expert advice out of normal working hours. We are able to undertake all aspects of maintaining your fire alarm equipment.

To comply with Health and Safety Regulations it is most important to ensure your fire alarm equipment is regularly serviced. It is a requirement to do so to meet British Standards! Failure can in effect give your insurance company a good reason not to pay in the event you have to make a claim

All fire systems maintained to BS 5839. Remember as a condition of meeting BS 5839 Part 1 the system must be regularly inspected and maintained at quarterly visits per annum. This is in addition to duties required by the system user.

What can we do for you?

As a minimum you must use qualified fire alarm engineers to carry out one annual and one bi-annual test and inspection each year.

Our fire alarm engineers can carry out all of the tests and inspections for you and we recommend that all fire alarm systems are tested at 3 monthly intervals by qualified engineers. The daily and weekly tests can be carried out by your own trained personnel. Call us on 0800 9751 911 for further information.

Fire Alarm Testing and Maintenance (BS5839: Part 1:2002 )

The following information lists the testing and maintenance schedule that is required.

Daily Inspection

Check that the Charger indicator shows. Inspect for any fault indicator showing or sounder operating. Inform the designated responsible person of any fault.

Weekly Test

Operate a call point or detector to test the system. Ensure that all indicators show by resetting according to the instructions provided with the panel and check that the internal sounder operates. Check that the sounders operate. Reset the fire alarm panel. Each week choose a different zone in rotation, so that way all call points are tested in rotation. Check all call points and detectors and ensure that none are obstructed in any way. Enter results of tests into log book.

Quarterly Test

Check all previous log book entries and clarify that any remedial action has been taken. Check the battery and its connections. Operate a call point or detector in each zone to test the fire alarm as per above. Remove mains supply and check that the battery is capable of supplying the alarm sounders.

Annual Test

Carry out tests as detailed above. Additionally test all detectors and call points and check for operation.

Every 2-3 years

Clean smoke detectors to ensure correct operation and freedom from false alarms. Special equipment is required for cleaning smoke detectors.

Every 4 years

Replace sealed lead acid batteries.

Data Cabling Installation The Easy Way...

When you need a reliable, professional, quality, cost effective Data Cabling company it's often hard to know who you can trust to give you a guaranteed quality of service at a price you can afford...

Data Cable installations may not be considered rocket science by some, but there are several criteria that need to be met if you want to ensure your cable installation is hassle free. If possible use a cable installer that comes by recommendation and understands your specific requirements. At the very least make sure the data cabling company that you choose has a track record of good installations and superior planning skills, quality products and years of experience.

Intalek Limited is a solid, trustworthy company who can provide you with a flexible, professional and cost effective data cabling installation service anywhere in the UK. Our Cabling engineers have the experience and understanding to take the pressure completely off you and make the installation as easy and smooth as possible, relieving you of additional and unnecessary stress.

* Horizontal and backbone cabling

* Network relocation, add-ons, and upgrades

* Cable testing and authentication with documentation of results

* Physical network planning and design services

* Cable management services

* Desktop installation services

* On-call consultancy, services and maintenance agreements

for network cabling infrastructure

* Physical site audits and inventories

* Project management services (On & Off site)

* Equipment tear downs and re-installations

* Scripted installations of equipment

* Active equipment installations

Intalek Ltd

Intalek Ltd